In the rapidly advancing world of smart electronics, the demand for more sophisticated, compact, and durable devices continues to grow. Among these innovations, wearable devices such as smartwatches, fitness trackers, and augmented reality glasses have captured the spotlight, blending advanced functionality with sleek designs. Behind the scenes, one critical manufacturing process plays a significant role in ensuring the precision and durability of these devices: spot welding.

What is Spot Welding?

Spot welding is a process where two or more metal surfaces are joined together by the application of pressure and heat. It is often used in the assembly of components in various industries, particularly in electronics. This technique is ideal for welding small metal parts quickly, making it particularly useful for the delicate and compact components found in wearable electronics.

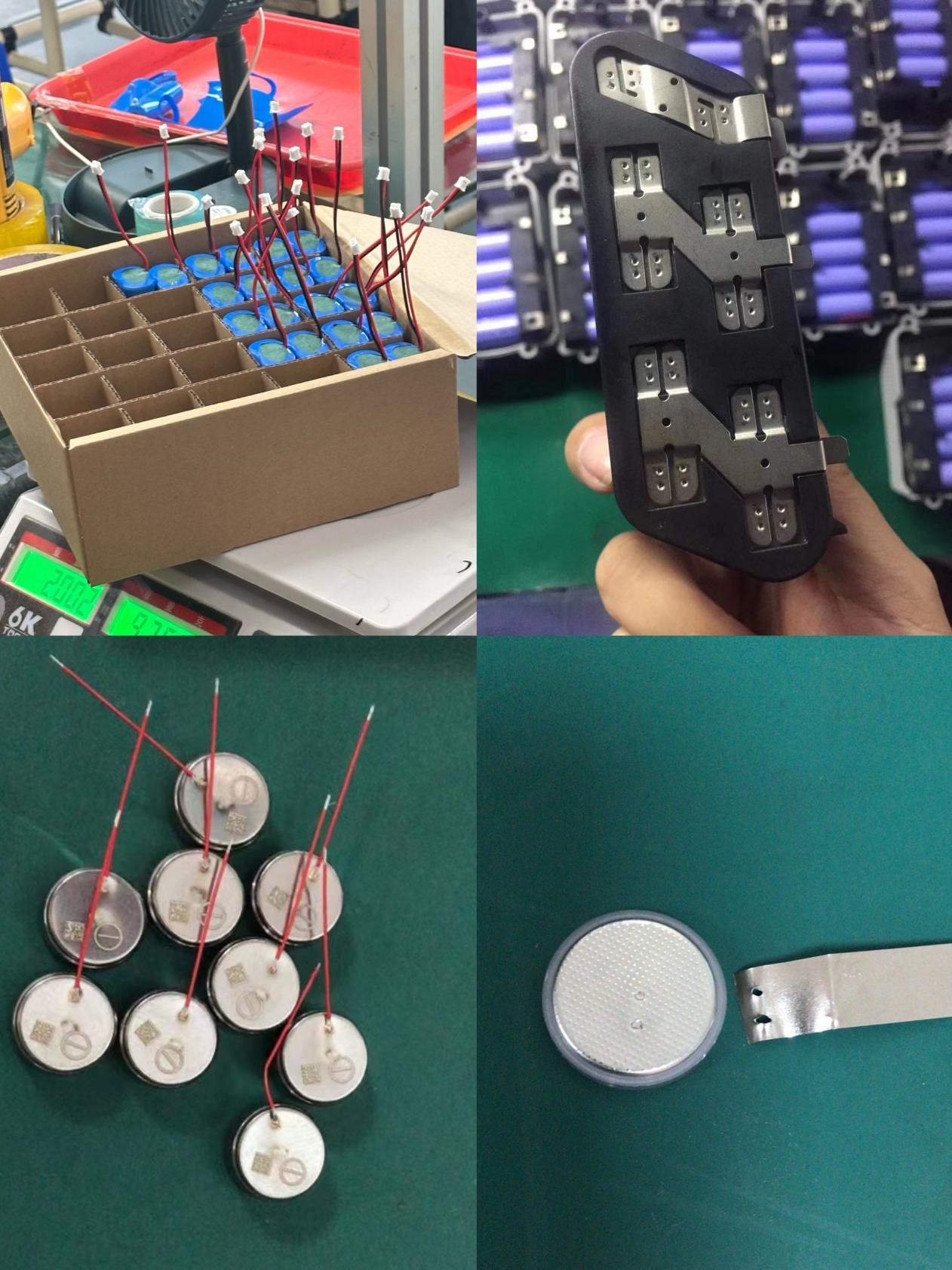

In wearable devices, spot welding is primarily employed to join battery terminals, circuit boards, and other internal metal components. These devices require a reliable power source, which is provided by the battery pack. Spot welding machines can effectively weld these battery packs, ensuring secure and durable connections.

This is where advanced spot welding machines, such as those from Styler, come into play, offering precision, stability, and speed.

Styler’s Spot Welding Machines: Precision, Stability, and Speed

Styler’s spot welding machines are known for their precision, stability, and speed—key features for manufacturing wearable devices. The machines deliver accurate welds for critical components like battery packs, ensuring secure connections. They maintain stable performance across various material thicknesses and operate at high speeds, improving production efficiency without compromising quality.

Why Spot Welding is Essential for Wearable Devices

Wearable devices must be able to withstand the rigors of daily use, which means they need to be both durable and lightweight. Spot welding offers several advantages for these requirements:

*Strength and Durability: Spot welding creates strong, permanent bonds between metal components, ensuring the longevity and reliability of the device. This is especially important for components like battery packs and connectors, which need to remain intact and functional even under stress or vibration.

*Compactness:As wearable devices are designed to be thin and light, spot welding allows for the most compact design. The process does not require additional adhesives or fasteners to connect small components, keeping the overall size of the device to a minimum.

*Efficiency: The speed and efficiency of spot welding make it an ideal choice for mass production. Manufacturers can produce large volumes of wearable devices in less time, reducing costs while maintaining high product quality.

Conclusion

As wearable devices continue to evolve and become more integrated into our daily lives, the role of precise manufacturing techniques like spot welding becomes increasingly important. With companies like Styler offering advanced spot welding machines that provide precision, stability, and speed, the electronics industry can meet the growing demand for durable, lightweight, and reliable wearable devices. Whether it’s a smartwatch or a fitness tracker, spot welding is a crucial process that ensures the integrity and longevity of these smart technologies, keeping them functional and ready for the future.

By leveraging the capabilities of Styler’s state-of-the-art equipment, manufacturers can ensure that the next generation of wearable devices is built to last, pushing the boundaries of both technology and design.

The information provided by Styler on https://www.stylerwelding.com/ is for general informational purposes only. All information on the Site is provided in good faith, however, we make no representation or warranty of any kind, express or implied, regarding the accuracy, adequacy, validity, reliability, availability or completeness of any information on the Site. UNDER NO CIRCUMSTANCE SHALL WE HAVE ANY LIABILITY TO YOU FOR ANY LOSS OR DAMAGE OF ANY KIND INCURRED AS A RESULT OF THE USE OF THE SITE OR RELIANCE ON ANY INFORMATION PROVIDED ON THE SITE. YOUR USE OF THE SITE AND YOUR RELIANCE ON ANY INFORMATION ON THE SITE IS SOLELY AT YOUR OWN RISK.

Post time: Feb-27-2025