Spot welding technology plays a vital role in driving the future of renewable energy solutions, especially when it comes to lithium battery welding. As the renewable energy industry continues to expand, the need for efficient, reliable spot welding machines has been growing. These machines are critical for creating strong and durable connections in lithium batteries, which are widely used in electric vehicles, energy storage systems and portable electronic devices.

Lithium battery welding requires precise and controlled spot welding to ensure the integrity and performance of the battery pack. These machines utilize high levels of precision and energy control to create consistent and reliable welds, which are critical to the safety and longevity of lithium battery packs.

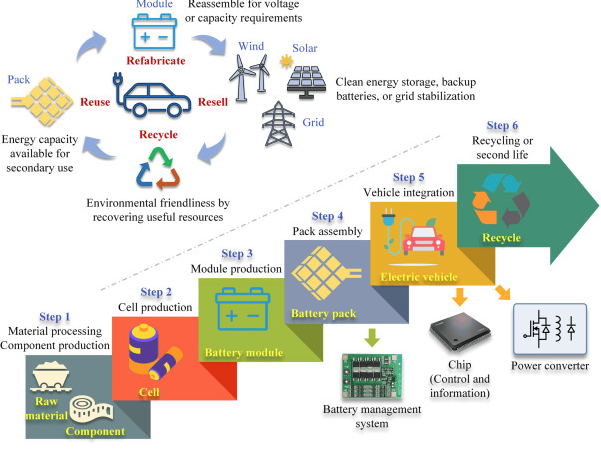

The development of spot welding technology has significantly contributed to the advancement of renewable energy solutions. By enabling efficient production of high-quality lithium battery packs, spot welders facilitate the widespread adoption of electric vehicles and energy storage systems. This in turn contributes to the reduction of greenhouse gas emissions and the transition to a more sustainable and environmentally friendly energy landscape.

In addition to lithium battery welding, spot welding technology is also used in the manufacture of solar panels and other renewable energy components. Creating strong and durable connections within these components is critical to ensuring their long-term performance and reliability. Spot welders are proven to help streamline the production process of renewable energy technologies, ultimately helping to increase their accessibility and affordability.

As the demand for renewable energy solutions continues to grow, the role of spot welding technology in driving this shift cannot be underestimated. Continued advances in spot welding machines, which are expected to further improve the efficiency and sustainability of renewable energy technologies, assising to shape the future of energy production and consumption.

At Styler, we specialize in the design and manufacture of advanced spot welding equipment tailored to the specific needs of battery manufacturers. Our cutting-edge machines incorporate state-of-the-art current control technology, ensuring precise and consistent welds for various battery applications. Whether you’re producing lithium-ion batteries for consumer electronics or high-performance electric vehicles, our innovative spot welding solutions empower you to achieve superior quality, reliability, and safety in your manufacturing processes. Welcome to joining in us and contribute to renewable energy.

Post time: Aug-29-2024